Did you know that the global boat market is expecting a $12 billion rise in value by 2027? The commercial vessel plays a large role in this increase for several reasons.

Higher supply chain demands have created an increase in the domestic fishing industry. In addition, more commercial fishing vessels on the water will increase demand for other crafts. Policing our waters is more crucial than ever before.

Governments also need to supplement their coast guard fleets. As well, the volume of patrol vessels will also increase. So, that means commercial boat manufacturers must prepare to keep up with demand.

Commercial boat manufacturers need all these skills and more. So much more happens after a commercial vessel is put on the water. The job of boat builders doesn’t end with the launch of the vessel.

So, if you want to know about how boat builders manufacture different vessels, keep reading. Here is a guide to commercial fishing vessels and other types of working boats.

From First Meeting to Design

There is a lot to planning the manufacture of any watercraft. But, for a commercial vessel, the stages for design, building, and testing are rigorous.

Commercial boat manufacturers must consider every detail, no matter how small. The time needed for boat builders to complete a project varies with the type of boat.

For example, consider the commercial fishing vessel length as a priority. Boat builders must know the type of waters each vessel sail in before deciding its length.

Another important consideration is the amount of technology each boat needs. For example, inland commercial fishing vessels won’t need the same tracking devices as seafaring vessels.

Regardless of the waterway, there’s no room for compromise with a commercial vessel. Every detail gets discussed with the buyer long before a design goes to production.

The boat manufacturer accounts for each component and where to source them. For example, in some cases, a boat trailer manufacturer joins the early design stages. At times, the same boat builders will construct the trailer as well.

Finished designs for commercial fishing vessels are all unique. That’s because the customer has input in every stage of production. As a result, the commercial vessel delivered to them is precise to their own specifications. Also, strict government standards are met with each component.

Our Changing Waterways

The environment and water traffic play large roles in changes to boat building. So, commercial bot manufacturers must keep up to date with new technology.

Noise restriction is an issue for any new commercial vessel. Marine life studies are showing the effects of traffic noise on fish species. Many boat builders will include these factors when designing new craft.

Patrol and rescue vessels are also affected by environmental changes. But, most of all, these commercial vessels need constant updating of new technology. Once again, commercial boat manufacturers must adjust to trends in satellite technology.

Police services and government buyers rely on boat builders to know these changes. Long after some commercial vessels go into service, they will need retrofitting.

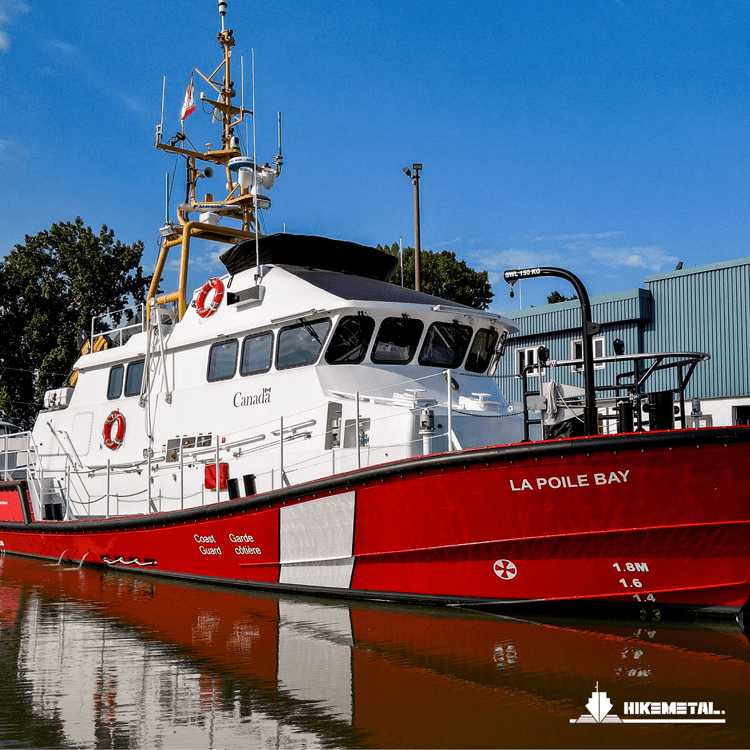

Boats like Coast Guard vessels have seen longtime service on the open waters. They still must follow new regulations. Refurbishments are regular maintenance for commercial boats.

Commercial boat manufacturers keep up with trends in fuel efficiency as well. New boats have better engines for cleaner running.

Commercial Boat Manufacturers Differ Greatly

There is so much more that goes into a commercial vessel. So, the best commercial boat manufacturers have specialized skills. Those skills are important long after boat builders deliver a new craft.

Commercial fishing vessels need regular maintenance. Fishermen count on these boats for regular service in their fleets. So, when a breakdown occurs, the boat builders are there for fast repairs.

This often involves portable rigging and lifts that commercial boat manufacturers keep ready. Whatever the issue, time out of the water is income lost. Commercial boat builders understand and will come to the boat’s aid whenever possible.

It takes a lot of different talents for boat builders to perform all these tasks well. There are staff members for every stage of the process for boat builders.

They need people who source materials for boating comforts. Seating for passengers and crew has different options. So do deck materials and cockpit stations.

Commercial boat manufacturers have designers experienced in their field. And, the most skilled trade of all is the people who design the vessel together. Experienced boat builders have crews to specialize in various stages.

There are welders for frame construction. Then, there are technicians for completing the electrical systems. Trim and paint experts then come in to finish a commercial vessel.

Also, where a craft gets built depends on certain factors. For example, there is the commercial fishing vessel length to consider. Larger boats get constructed at an indoor facility because of the time it takes to build.

Climate control is a factor in building a quality commercial vessel. So, commercial boat manufacturers must have proper fabricating plants to protect the ship. All of these factors go into building the best commercial vessels.

A New Perspective

Quality commercial vessel construction takes more people and skill than meets the eye. Commercial boat manufacturers have to wear many hats. But, so much rides on the expertise of boat builders to perform at a high level.

Are you buying a commercial vessel soon? Then you’ll want to work with boat builders with extensive experience. Hike Metal has been crafting quality ships for more than sixty years.

So, give us a call and set up a consultation to ensure the best commercial vessel you will buy.